One of the most important and immediate factors for an organization facing quality issues is the effectiveness of frontline training. For both containment and internal operations, training can directly impact how the issues are handled. For inspection teams, a solid training program can mean higher quality inspections, performed faster and more scalable than otherwise possible.

For internal quality assurance operations, it means up to a 75% better on-time delivery and quality level than without. Embracing technology is helping organizations of all sizes get the most out of their employees without an increased risk of quality issues. For organizations that are actively looking for ways to benefit from improved training programs, there are three key areas in which it can be improved:

Connecting Workers to One Another

Technology provides employees with easier ways to summon help, escalate their concerns or questions, and teach others on the job when new processes or problems arise. Most importantly, they are able to do so at the point of learning.

This type of collaborative training better defines who trains new employees, the training materials they will use and the best practices communicated to employees. It ensures that two new hires onboarded around the same time will receive similar training even if they work different shifts and stations. Higher levels of communication between every member of the organization ensure no issues in this regard.

This helps to address high rotation issues as well - when someone is trained in a small number of stations, they can’t rotate to new positions when there is an unexpected departure or shift in demand. For quality containment, in particular, this is vital. Employees need to be comfortable and flexible in their approach so that they can pick up new procedures with the context of the system they already know rapidly.

Digital Work Instructions and Progressive Checklists

Digital checklists and work instructions are replacing paper-based resources, allow workers to pull the information they need when they need it. Progressive technology makes the system more flexible as well, providing bite-sized bits of knowledge that are retained at higher rates.

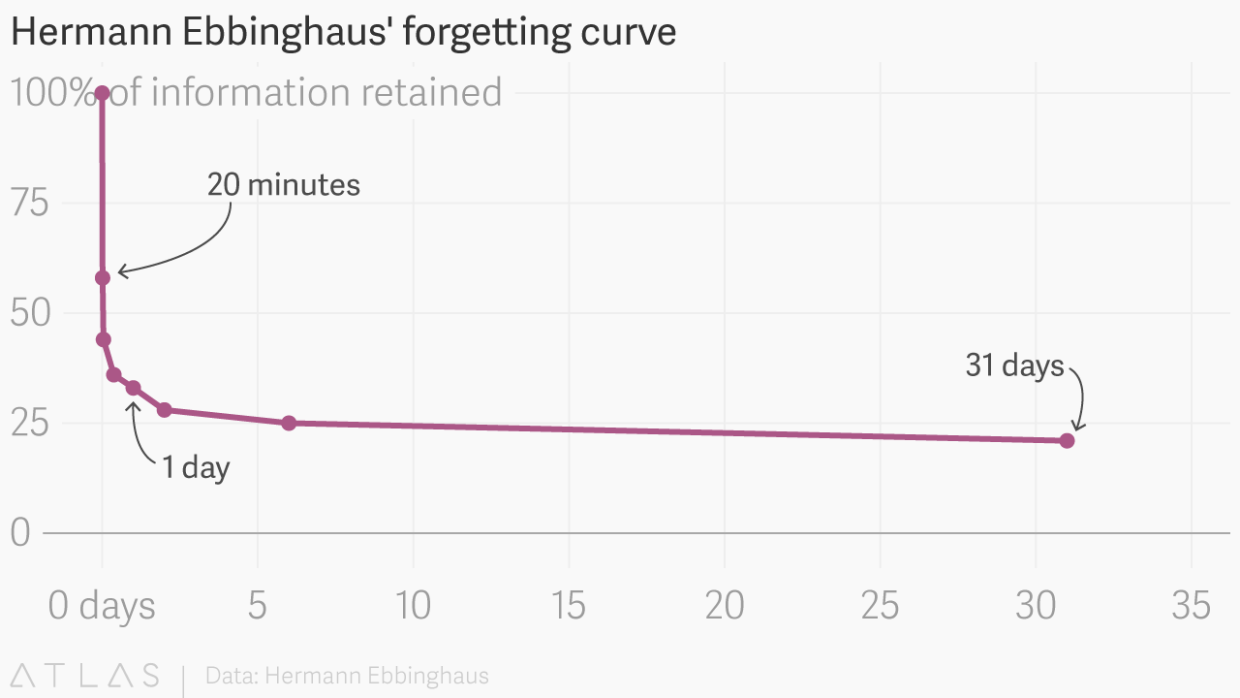

On average, employees retain only 10-25% of what they learn. The Forgetting Curve represents the time it takes for someone to lose the information provided, and the frequency at which retraining is needed.

Microlearning is designed to address the forgetting curve by presenting only bite-sized bits of information at the point of need. Instead of jamming an entire job’s worth of information into someone’s head over the course of a week, training systems are designed to dole out information only when it is needed. Not only does this lead to higher knowledge retention, but it also makes it easier to retrain employees. When a new process is implemented, it can be pushed to the central training platform, and relevant employees are notified of the new processes.

Training Management Platforms

Supervisors can pull reports and evaluate performance from within a centralized system. It’s more efficient and more accurate than the traditional paper-based manual inspection process. Not only does this lead to fewer supervisors on the floor, reducing overhead and improving efficiency; but it provides greater transparency to both the management and stakeholders who need to receive periodic updates.

There are several ways to implement such systems. PTI uses the Smart Work Station connected worker platform, for example. This centralizes the performance data, training cadence, and upcoming needs across all parts of the organization into a single easy-to-access interface that can be shared with all members of management.

The Tools of the Trade

To effectively implement such a program, technology needs to provide a comprehensive platform on which to build a training regimen. That means including the following resources:

- Flexible content solutions. Content should be presentable as written checklists, videos, interactive guides, and whatever else is going to best fit the working conditions, learning style, and in-the-moment needs of your front line workers.

- Data recording. These systems need to be able to record and analyze data relevant to the specific tasks being performed. Whether from a physical workstation, sensors installed throughout the organization, or trainer/supervisor data, this allows for a much greater level of transparency on the floor.

- Safety and quality resources. Specific processes should be clearly outlined to map the best practices for your frontline workers around safety and quality.

The end result of such a system is better performance, reduced overhead from excessive training and supervision, and a much better-prepared frontline when a new project starts. For containment, this means a more scalable response to immediate needs. For internal teams, it means reduced risks of quality issues and a safer frontline.

Learn more about the importance of proper training in quality containment and the impact it can have on your bottom line in our eBook, The Importance of Proper Training in Quality Containment